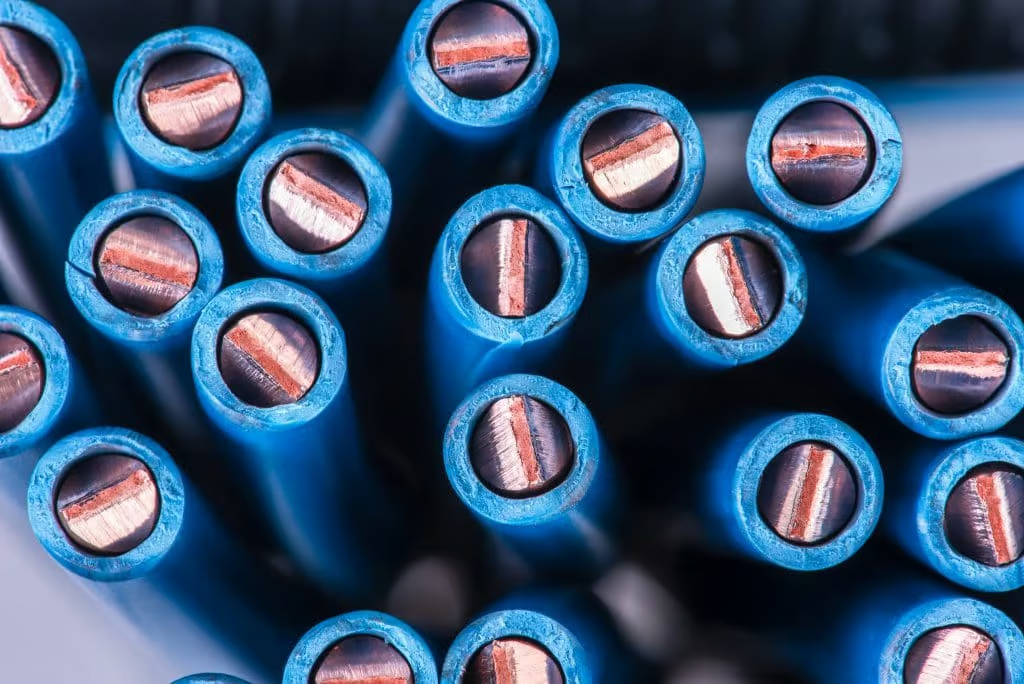

Wire and Cable

Kraton polymers can be found in a variety of wire and cable products. Kraton G polymers can be formulated for use in flexible cords, industrial cords, primary automotive wires, control wires, booster cables, welding cables, molded plugs, and connectors, among other applications. Kraton FG polymers can be used to improve the compatibility of flame retardant fillers and polymer matrices.

Wire and Cable

Wire and Cable Features and Benefits

Kraton polymer-based compounds can be relied on by wire and cable designers, application engineers, and processors to deliver:

Products for Wire and Cable

Kraton G

Kraton™ G polymers, second-generation styrenic block copolymers (SEBS/SEPS), offer superior compatibility, UV resistance, and durability for versatile applications. Available in various physical forms, including free-flowing powders, they ensure efficient processing and handling.

Kraton FG

Kraton™ FG can be used as polymers for cable sheathing enhance adhesion to various substrates and serve as efficient impact modifiers for tough engineering thermoplastics.